External Wastegate Piping

What is a Wastegate pipe?

A waste-gate pipe is a pipe or tube that connects the external waste-gate outlet back into the exhaust. This can also be a pipe that is vented to atmosphere which can be know as a "screamer pipe"

The screamer pipe can be a short pipe that is vented out the bottom of the vehicle up by the engine/gearbox area or it can be run to the rear or the side of the vehicle as well. This can also run small mufflers and resonators to keep the noise level down.

Generally the shorter the pipe, the louder the waste gate sound will be exiting the pipe. i.e if the pipe is run to the rear of the vehicle it will not be as loud as if it was exiting over a 500mm length of pipe. The noise level will also depend on the size of the turbo and external waste-gate that is being used.

If you have a large turbo and only running 10psi of boost then the waste-gate noise level will be a lot louder than if you are running 30psi of boost because the waste-gate has to vent more volume (exhaust gas) to keep the engine running at 10psi.

Back into Exhaust vs Screamer Pipe

This information is vital to a successful piping merge

Back into exhaust

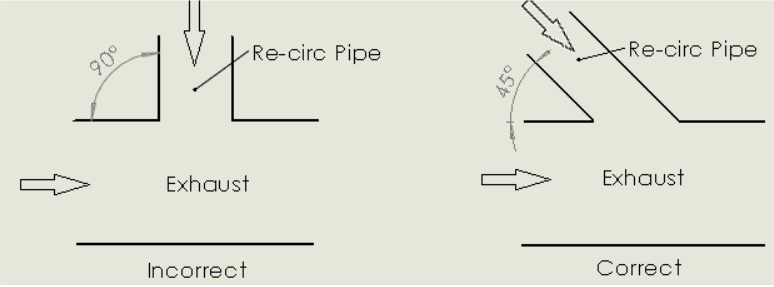

It is important that when running the wastegate piping back into your exhaust that a low merge angle is used. This helps the gas merge into the exhaust and prevents a bottle neck when the two gases meet. A large oval hole is ideal where the re-circ pipe joins into the exhaust i.e the hole should be 1.5 times bigger than the pipe size used. This will ensure there is no restrictions when gases are entering the exhaust and will help prevent boost spiking from the gas not being able to exit the external waste-gate quick enough.

When running the waste-gate pipe back into the exhaust this adds more volume/gas into the exhaust which can increase the back pressure. One way to compensate for this is to step the exhaust up one size where you merge the gate in i.e if you are running a 3" down-pipe then step the exhaust up to 3.5" where your waste-gate pipe goes into the exhaust especially if you are running a large waste-gate of 60mm.

Waste-gate Tube Starters

These are laser cut sections of tubes to run your waste-gate back into your exhaust (plumb-back). Take the guess work out of merging the two pipes together. These have been developed for optimal angle for the gases to exit the waste-tube without restrictions. They are also long enough for v-band flanges to be welded on with clearance for the clamp to be accessed and to be removed without issues.

Screamer pipe

A screamer pipe is a pipe that is vented straight to atmosphere like the photos below. This is basically an exhaust leak of sorts, when the valve opens from the external waste-gate the exhaust gases from your manifold exit the pipe making a screaming type noise when the vehicle is under boost.

"QUICK TIP"

"IF YOU ARE RUNNING A SCREAMER PIPE MAKE SURE TO HAVE THE PIPE HIGHER THAN THE LOWEST POINT OF YOUR VEHICLES CHASSIS OR SUB-FRAME TO ELIMINATE THE PIPE CATCHING ON THE ROAD" BUT MAKE SURE ITS POINTING AWAY FROM ANY PART OF YOUR VEHICLE THAT CAN MELT FROM HEAT

Choosing Your Wastegate Piping Size

A 38mm piece of tube is measured from the outside diameter. The wall thickness of tube is generally 1.5mm, so this will make the inside diameter of this piece of tube to be 35mm. In some cases this can restrict the gas flow.

One way to compensate for this so the gases exit without issues is to step the tube up one size.

Example=

38mm or 40mm waste-gate = 44mm tube

44mm or 45mm waste-gate = 50mm tube

Wastegate Pipe Bracing

The external waste-gate pipe often isn't considered on the list of components to brace. When you have a long waste-gate pipe that is venting to atmosphere (screamer pipe) then the weight from the pipe and the vibration that the pipe will create can cause issues with manifold waste-gate take off ports cracking. As you can see in the photo below a simple section of flat bar is all it takes to support the weight. We also use a removable type setup for ease of fitment so the parts can all be taken out separate from each other. To view our full write up on Bracing Click Here: